By Sue Dickens

If you are in the market searching for a flow meter, you must have come across a diverse range of these devices. Of course the importance of liquid and gas flow measurement cannot be underestimated. There is so much you gain by measuring the volumes of liquid and gas in your application. Whatever your application is, coriolis flow meters increase accuracy in your flow measurements. This in turn reduces wastage and puts you in control.

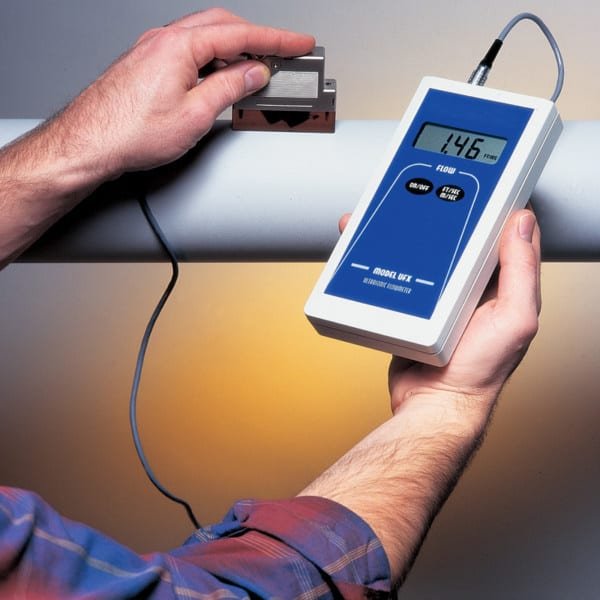

Flow Meter

What to Know about Coriolis Flow Meters

These flow meters operate on the simple, proven and tested principle that if a particle inside a rotating body changes direction away or towards the center of rotation, it will generate inertial force which will act on the body. This device creates rotating motion inside vibrating tubes where the flow is going through.

The inertial force that results is proportional to the mass flow rate. In essence, by measuring the inertial force of deflection, your flow meter gives you the mass flow rate. One of the best reasons given for investing in a Coriolis flow meter is its ability to provide direct mass flow reading in addition to volumetric flow rates, process temperature, and density readings.

Why the Coriolis Flow Meters Stand Out

There are many flow meters you can choose for your application but there are reasons why more applications are going for coriolis flow meters. Here are a few of these reasons:

- Multi-parameter measurement capability – Other than the direct mass flow reading you will also get other measurements of important parameters including process temperature, volumetric flow rates, and density readings. You can also get inferred readings for density-dependent parameters such as degrees Baume, water-in-oil percentage and degrees Brix.

- High performance – This flow meter is independent offlow profile, flow turbulence and density changes.

- Low maintenance – There is no risk of wear and tear which would require expensive repairs and maintenance. With no wearing parts to worry about, you are assured of smooth operations.

- Flexibility – This flow meter can measure difficult handling fluids and this is an important factor when you have such flow at your application. The device is bi-directional, making measurement easy in any type of setting.

- High accuracy levels – They are accurate for Btu and other measurements.

- Liquid calibration for gas use is an important feature for applications dealing with both types of flow.

- Versatile applications – These flow meters can be used effectively in a wide range of applications including food and beverage processing, paint companies, process control, petrochemical applications, oil and gas processing among others.

In summary, the technology used in coriolis flow meters rates highly for liquid flow. They guarantee high accuracy levels and can handle varying temperatures, pressure and viscosity. You can choose from among the different tube systems including U-Tubed (UT) flow meters, Micro Bend Tube (MB) flow meters and Delta Tubed (DT) flow meters.

When shopping for any of these flow meters, compare their accuracy, types of flow rates where they work, the reputation of the brand, output and temperatures.

Author Bio

Sue Dickens is a flow meter specialist based in Houston, Texas. He has reviewed different systems including the coriolis flow meter. Sue lies with her family in the city. Visit her blog here for more information.

If you would like to submit a guest post on food, wine or travel to Where and What in the World, I would be happy to feature your travel experience , drink, special wine tasting, or family or simply delicious recipe. If you go to submission tab, you will see how to submit, as well as have the opportunity of telling me if you would like to would like to be a regular contributor. When uploading a file for submission, you are also able to upload jpegs. Please feel free to put a last paragraph about you and a link to your profile. No html please. You can also include a head shot.